Supplier Of Industrial and Marine Equipments

- Mail Us: sales.svexim@gmail.com

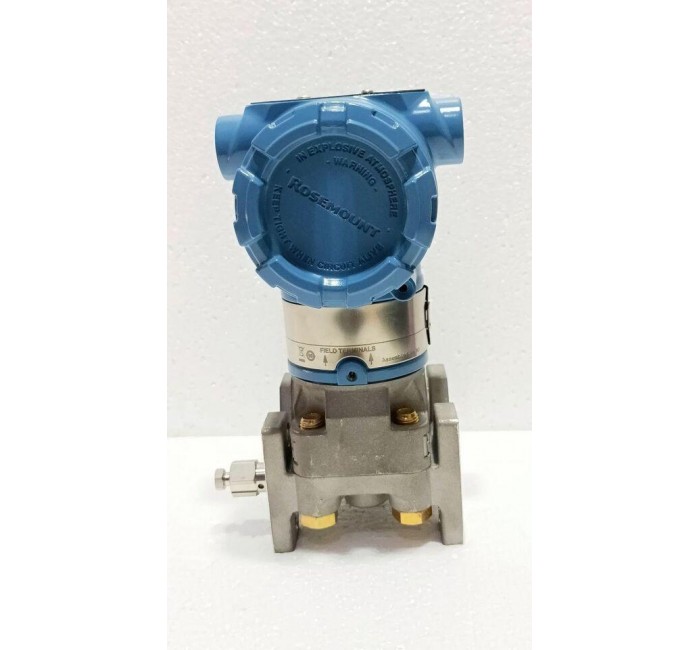

Rosemount 3051CG4A02A1AH2B1 SW 1.0.2 HW 1.0.0 Pressure Transmitter

Avoid high points in liquid lines and low points in gas lines.

Make sure both impulse legs are the same temperature.

Use impulse piping large enough to avoid friction effects and blockage.

Vent all gas from liquid piping legs.

When using a sealing fluid, fill both piping legs to the same level.

When purging, make the purge connection close to the process taps and purge through equal lengths of the same size pipe.Avoid purging through the transmitter.

Keep corrosive or hot (above 250 °F [121 °C]) process material out of direct contact with the sensorn module and flanges.

Prevent sediment deposits in the impulse piping.

Maintain equal leg of head pressure on both legs of the impulse piping.

Avoid conditions that might allow process fluid to freeze within the process flange.

Transmitter Type:- Gauge pressure transmitter

Pressure Range:- -14.7 to 300 psi / 3 psi minimum span

Output:- 4-20mA with digital signal based on HART protocol

Rosemount 3051CG4A02A1AH2B1 SW 1.0.2 HW 1.0.0 Pressure Transmitter

Avoid high points in liquid lines and low points in gas lines.

Make sure both impulse legs are the same temperature.

Use impulse piping large enough to avoid friction effects and blockage.

Vent all gas from liquid piping legs.

When using a sealing fluid, fill both piping legs to the same level.

When purging, make the purge connection close to the process taps and purge through equal lengths of the same size pipe.Avoid purging through the transmitter.

Keep corrosive or hot (above 250 °F [121 °C]) process material out of direct contact with the sensorn module and flanges.

Prevent sediment deposits in the impulse piping.

Maintain equal leg of head pressure on both legs of the impulse piping.

Avoid conditions that might allow process fluid to freeze within the process flange.

Transmitter Type:- Gauge pressure transmitter

Pressure Range:- -14.7 to 300 psi / 3 psi minimum span

Output:- 4-20mA with digital signal based on HART protocol